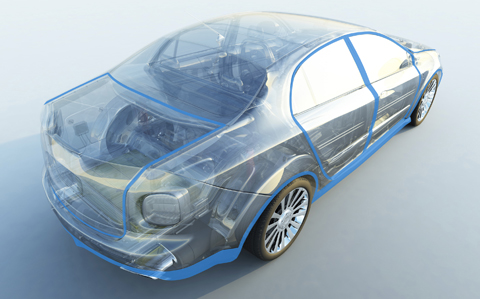

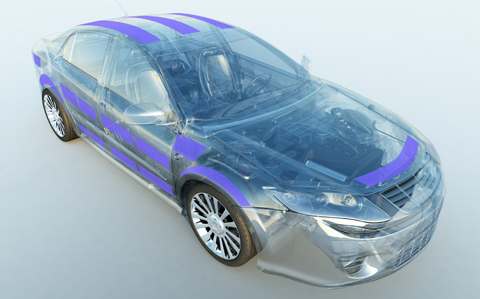

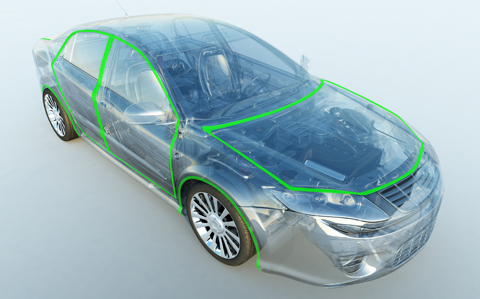

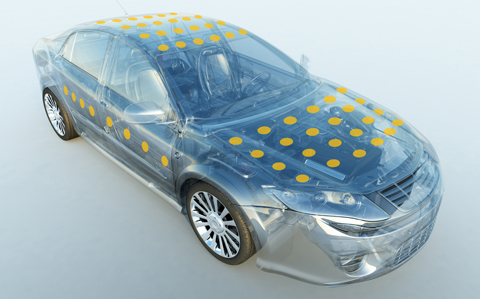

SOUNSECURE™ products are specifically designed to prevent noise, vibration, rust and water entry. They are applied to inner surfaces of automobiles over E-coat and before the painting process.

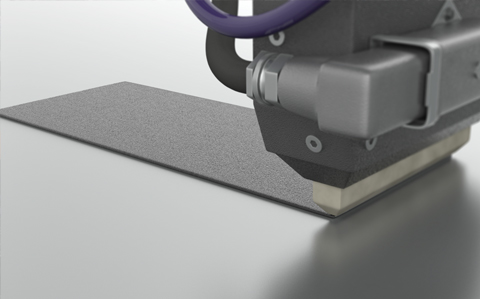

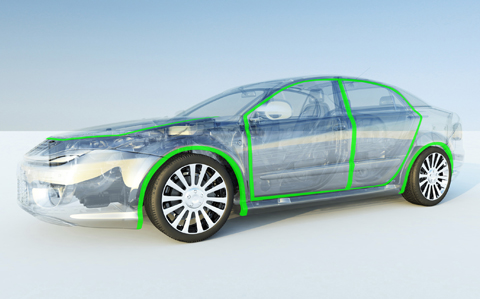

SOUNSECURE™ Hybrid NVH Metal Reinforcement is a single-application material that delivers excellent strength, flex and sound dampening to automotive body panels.

It was first put into OEM production in November 2014 and is now embraced by progressive automakers because of its immediate benefits in both performance and to the bottom line.

They deliver outstanding durability and will not compromise a vehicle’s structural integrity, comfort and safety.

UNISEAL anti-flutter products provide optimal isolation of sheet metal components from inner reinforcements while improving manufacturing efficiency and quality.